Capabilities

MHR is currently accepting new customers for small to large production machining. Contact MHR Inc. for more information.

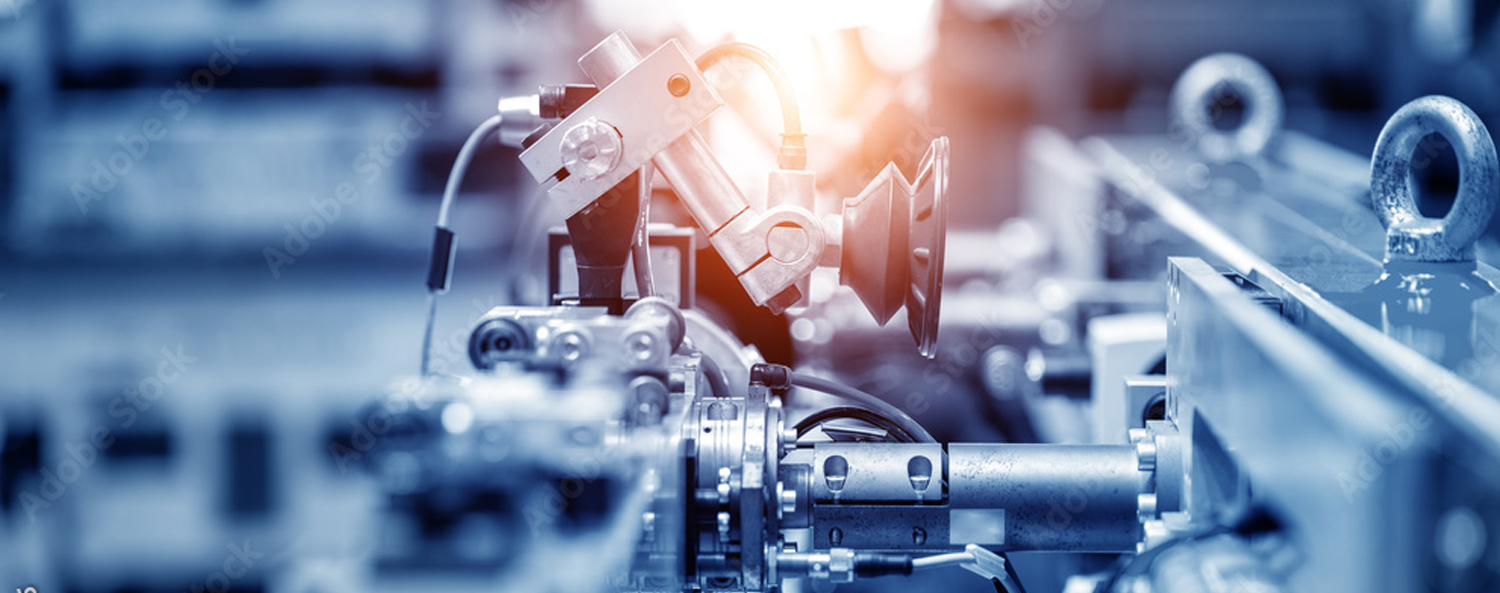

The Machine Shop at MHR offers a full range of services. We have CNC turning and milling centers equipped to handle 3rd and 4th axis work. Our CAD and CAM software technology supports solid modeling and 5 axis tool path generation. MHR’s premium quality equipment combined with our staff’s years of tool and mold making experience will allow MHR to deliver to you the highest quality of product possible.

Jig, Fixtures, Small Dies, Mold Building, and In house CAD engineering and CAM programming. We offer quick response, quality workmanship and personal service. We invite you to visit us and see what we are all about.